Project overview

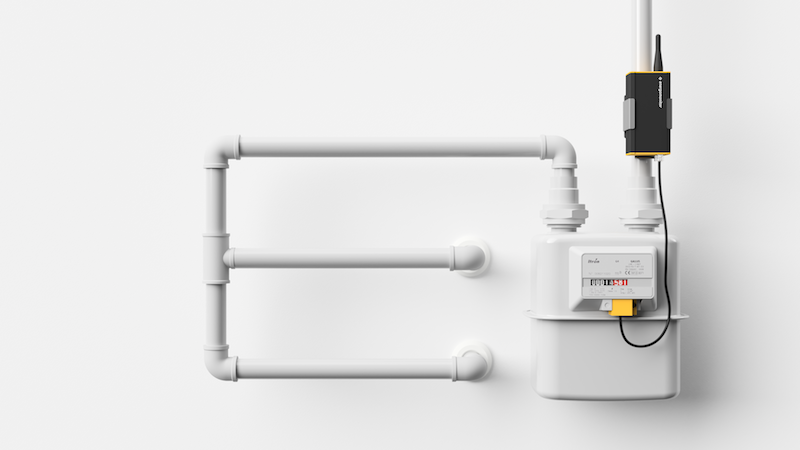

- Development of a device that uses a gas meter’s pulse counter to monitor gas consumption in real-time.

- Part of Energomonitor, an IoT system for online monitoring of utility consumption.

- Developed in two time periods; from November 2015 to March 2016, and from October 2016 to December 2016.

Problem: Why gas meter monitoring?

Energomonitor started with electricity consumption monitoring, but users soon began to demand monitoring of other utilities as well — most of them, gas. Knowledge of gas consumption is crucial not only for costs overview, but also for safety, due to a possibility of a gas leak.

Key decisions

- We decided to read the consumption data from an pulse counter, which can be found on many gas meters. This is the easiest way to access the consumption data for most users.

- At first, we were buying probes for reading the pulse counter from a third-party manufacturer. Later, we started to develop our own probes because of the price and distribution flexibility.

- From the very beginning, the device was meant as part of the Energomonitor ecosystem, and it was supposed to use the Energomonitor application for data collection, storage, and visualisation.

- The visual design of the sensor was not a priority as the most of the time, the device would be placed a near gas meter at the utility part of the house.

Key development steps

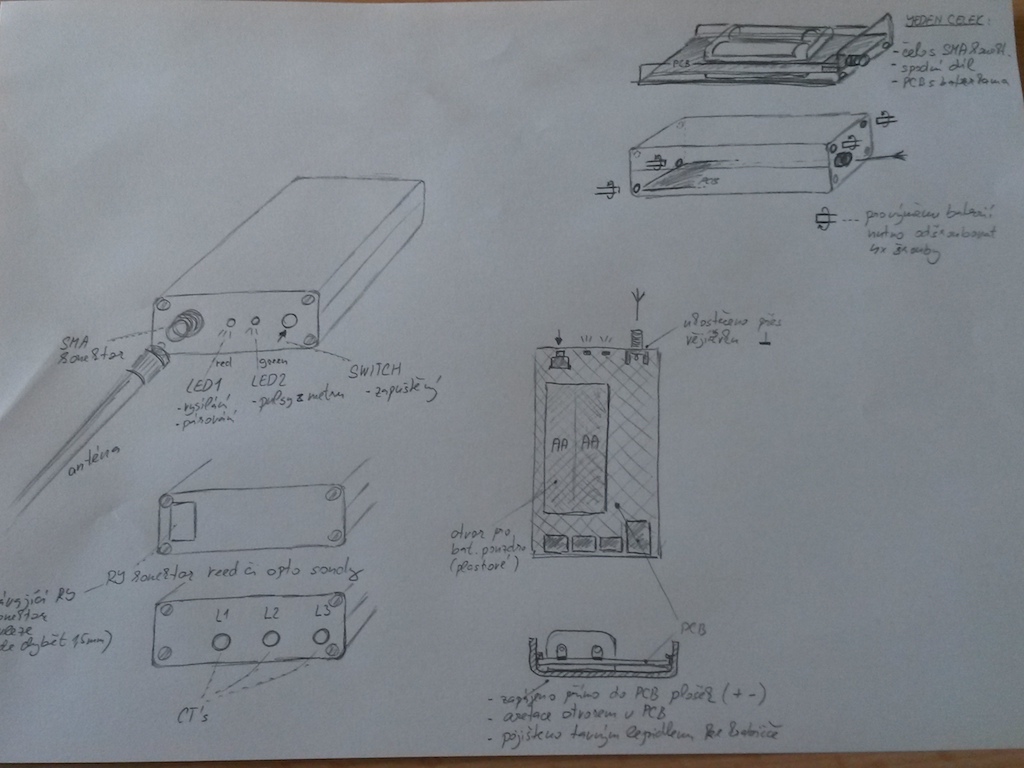

Transmitter

- Every 5 seconds the transmitter gets the data from the probe and sends it further to the Energomonitor system.

- The device converts pulses read by the probe using an IPU (impulse per unit) coefficient, computing the immediate gas consumption (in m3) and heat energy produced by combustion (in Wh).

- As there is usually no power plug near the gas meter and we wanted the installation to be as user-friendly as possible, we made the transmitter battery-powered.

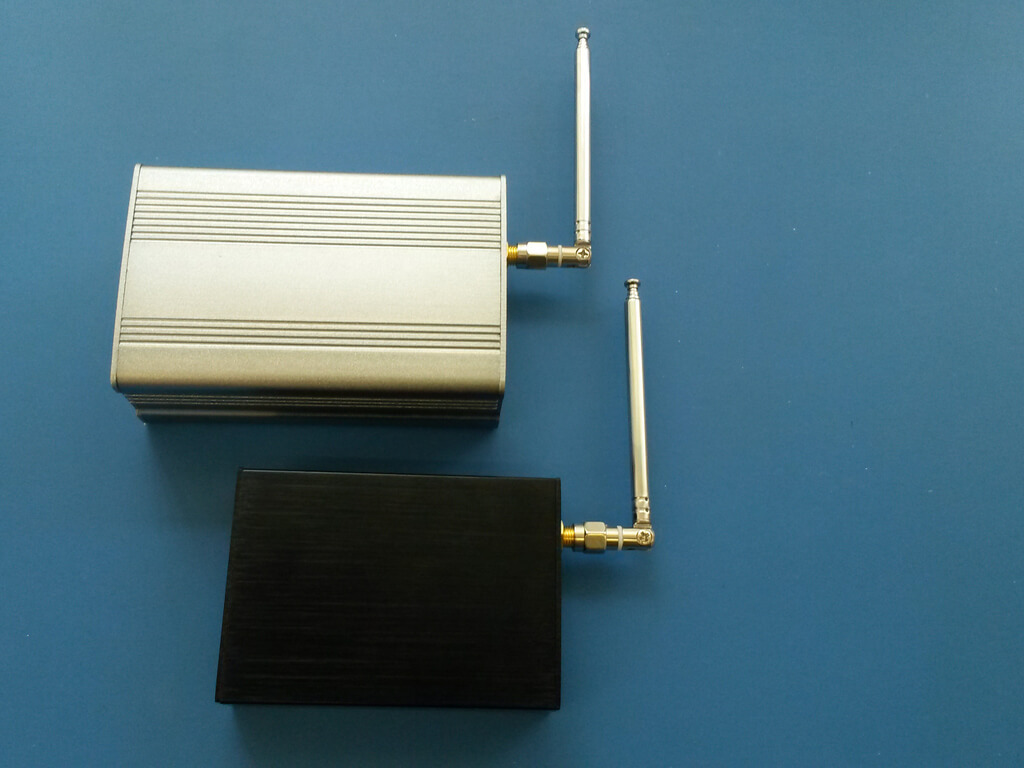

- Due to different needs of antenna strength for different users, we built a standard SMA interface into the device, which allows the replacement of our default antenna with a stronger one if necessary.

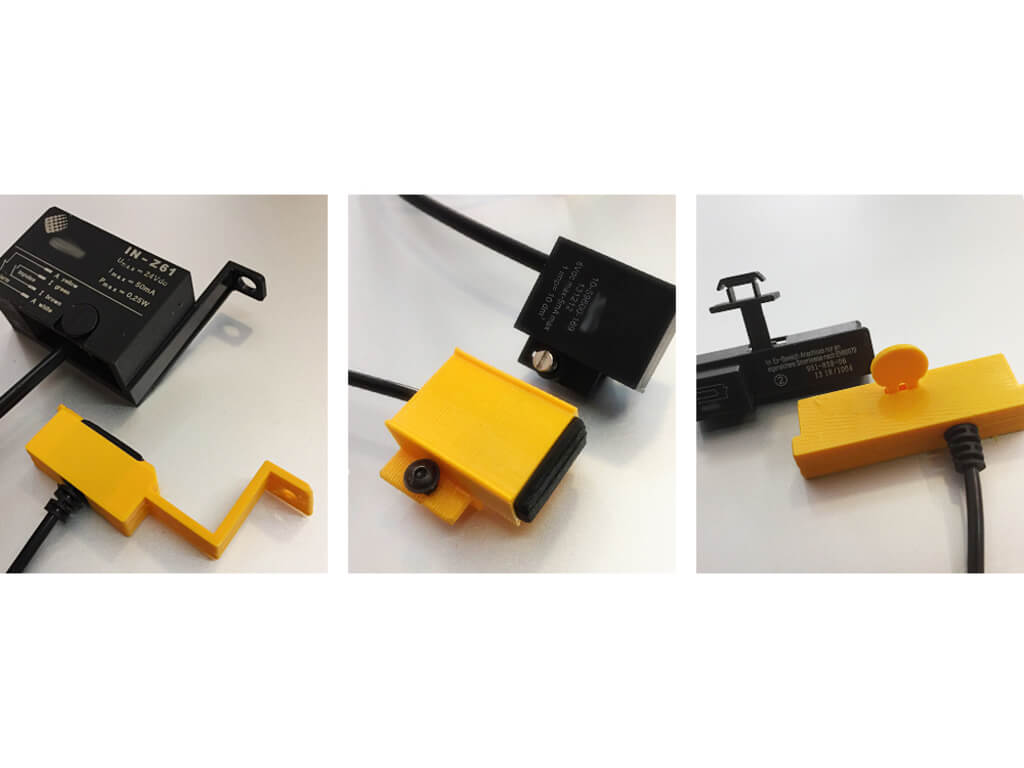

Gas probe manufactured by a third-party

- At first, we used probes supplied by gas meter manufacturers for reading the pulse counter.

- The gas probe is a reed switch wrapped in a plastic cover which matches the shape of the pulse counter on the gas meter, to which it is mechanically attached.

- Many pulse counter shapes exist, but we selected three of them, which covers around 95% of Energomonitor user requests.

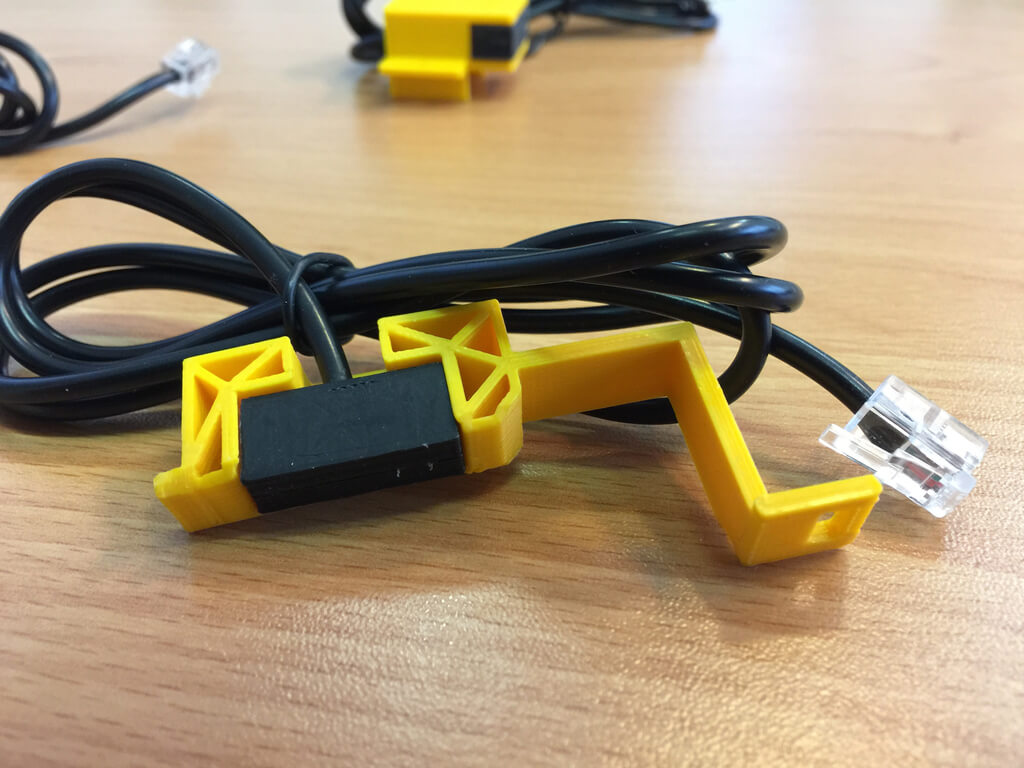

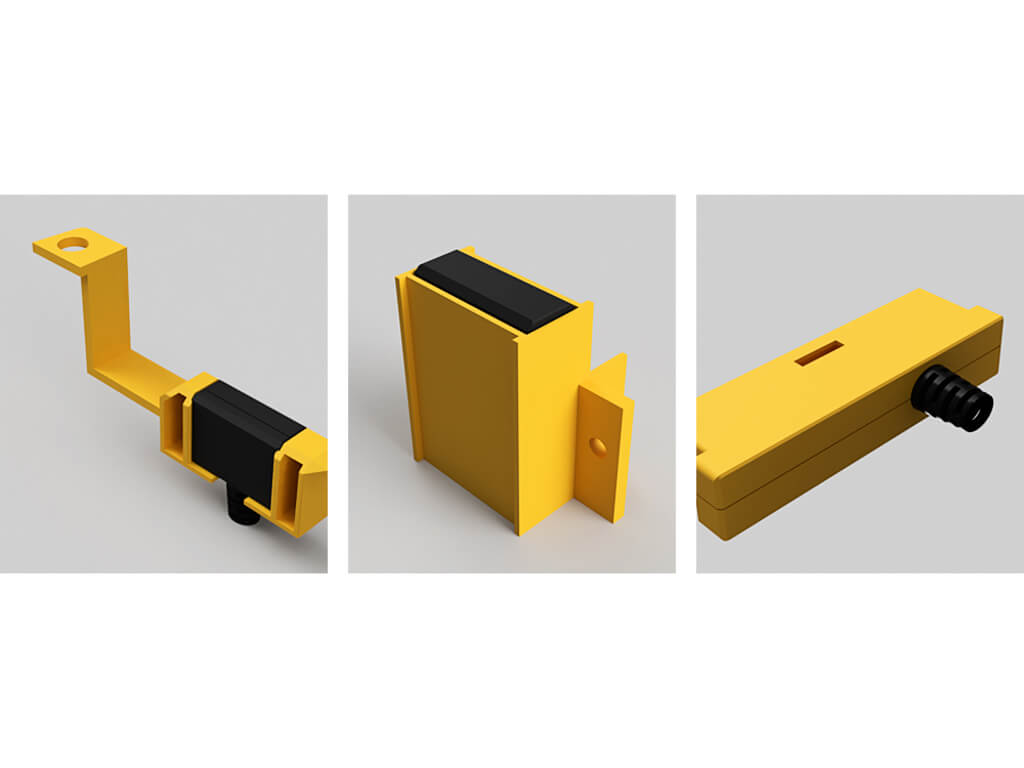

Gas probe manufactured in-house

- We were buying the gas probes from gas meter manufacturers, whose price politics is not friendly. This resulted in high cost, which pushed us to start making these probes on our own.

- Gas probes consist of a plastic cover and very simple electronics inside. We started to make CAD designs and first prototypes on a 3D printer. We tested the prototypes on real gas meters, calibrated the metering accuracy, and eventually finalized the probe forms.

- As a result, we reduced the probe price from €28 to €2 per piece.

Deployment

- Right now Relaysense Gas is being sold as the part of the Energomonitor system.

- The device provides an excellent price/information value ratio, together with easy installation.

- The installation package contains all three probe types because users usually don’t know which type of gas probe they need before they try it. Including all the probe types became possible because we lowered the gas probe cost.

- The sensor is battery-powered, with a battery life of more than 2 years. There is no need for maintenance during its lifetime.

- The range of the radio link is up to 100 m, depending on wall shielding and electromagnetic interference.

- Data visualisation is provided by the Energomonitor application, with a possibility of export through an API.